Increasing Efficiency in Highway-Rail Grade Crossing Inspections

The Challenge

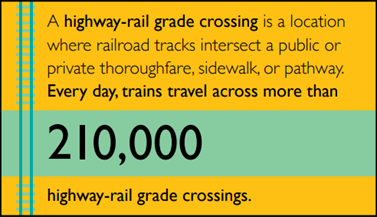

Of the 210,000+ highway-rail grade crossings in the United States, some are inspected only every 2 to 3 years.

Of the 210,000+ highway-rail grade crossings in the United States, some are inspected only every 2 to 3 years.

Roadway maintenance and vegetation growth can frequently change the conditions of the road, including causing humped crossings—areas in which the tracks are at a significantly higher elevation than the roadway that approaches them. Humped crossings can be dangerous for larger vehicles, such as buses and tractor trailers, as their low ground clearance may cause them to get stuck or “hung up” at these crossings and result in a collision.

In addition, at some crossings, a driver’s vision may be obstructed by vegetation, signs, parked cars, or a variety of other temporary conditions that can make it difficult to see approaching trains.

Inspecting crossings more frequently would improve data on whether and how highway-rail conditions have changed over time and help prioritize needed maintenance.

The U.S. Department of Transportation (U.S. DOT) Small Business Innovation Research (SBIR) program worked to address these challenges through its annual Phase I solicitation.

In 2020, FRA sponsored an SBIR project that would create a drone-based highway-rail grade crossing inspection system to more efficiently and frequently assess the safety of crossings. VisioStack, a company based in Greenville, South Carolina, was awarded SBIR funding to develop and demonstrate its proposed solution, the Aerial Crossing Inspection System (AXIS).

(FRA selected an additional small business, MTRI Inc., to develop a different solution to this same SBIR topic. Read about MTRI Inc.’s Crossing-i system.)

Small Business: VisioStack

Location: Greenville, South Carolina

Project: Aerial Crossing Inspection System (AXIS)

Funding Agency: Federal Railroad Administration

Phase I: $146,727

Phase II: $297,087

The Technology

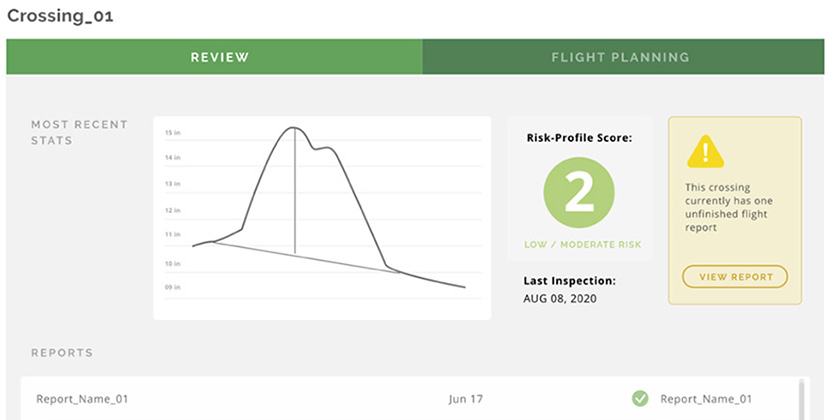

The Aerial Crossing Inspection System (AXIS) uses drone technology, cloud-processing, and clustered computing to perform inspections and determine the “risk profiles” of highway-rail grade crossings. Key metrics that help build a crossing’s risk profile include the maximum vehicle clearance, identification of required signage, and line-of-sight conditions.

AXIS uses a standalone mobile app that pre-plans drone inspection flight paths, uses photogrammetry to create a three-dimensional model of the crossing, and generates detailed reports that are summarized on a dynamically updated dashboard.

This technology enables stakeholders—such as railways, state departments of transportation, and crossing inspection consultants—to inspect crossings more frequently for key features such as humped profiles and limited lines of sight, helping them prioritize maintenance activities that improve the safety of the traveling public.

The Future

With the development of the standalone mobile app during its Phase II SBIR project, AXIS is ready to be deployed by stakeholders to inspect highway-rail grade crossings.

Users will be able to perform the entire inspection process through the mobile app, including planning flights, collecting images, and analyzing conditions at crossings.

AXIS can also be paired with VisioStack’s mobile Field Inspection app to help users inspect a variety of asset types and automatically update the FRA Grade Crossing Inventory, which can help organizations stay compliant with inspection requirements.

The technology used in this system can be expanded to further improve the way that railroad infrastructure is inspected. In the future, VisioStack may enhance the technology for specific use cases, such as allowing the inspection of multiple crossings during a single drone flight and improving object detection models to determine the presence of key signage more accurately.

The Impact

AXIS can help stakeholders responsible for managing highway-rail grade crossings to perform inspections more efficiently, giving them faster access to reliable data that can inform maintenance plans and help target safety improvements at crossings where problems exist.

This technology also allows for more frequent inspections, reducing the time it may take to address issues that cause hang-ups or obstructed views at crossings, potentially decreasing the number of harmful—and sometimes fatal—highway-rail incidents.

How SBIR Helps

The Phase I and Phase II SBIR awards have made it possible for VisioStack to advance the capabilities of drone-enabled infrastructure.

“This SBIR award has helped fund the development of a product that fits a need in the industry,” said VisioStack Operations Manager Joshua Doran. “Through this award, VisioStack has connected with several key stakeholders who have not only provided valuable feedback for the development of the system but have also opened doors for further marketing and business development opportunities.”

About SBIR

The U.S. Department of Transportation’s highly competitive Small Business Innovation Research (SBIR) program awards contracts to domestic small businesses to pursue research on and develop innovative solutions to transportation challenges.

Moreover, the SBIR program encourages small businesses to engage in federal research/research and development (R/R&D) that has the potential for commercialization. The program awards contracts in two phases, and it recognizes a third phase leading up to commercialization. See Past Solicitations and Awardees for more information.