Volpe’s Innovations from the 2016 Joint Rail Conference

From eliminating broken rails and combating punctured tank cars, to making stronger interfaces between rail ties and ballast, Volpe engineers support the Federal Railroad Administration (FRA) Office of Research and Development in making passenger and freight rail travel safer.

Volpe’s range of rail expertise was on display at the American Society of Mechanical Engineers 2016 Joint Rail Conference in Columbia, South Carolina. Nine Volpe staff—David Y. Jeong, Benjamin Perlman, Michael E. Carolan, Hailing Yu, Brian Marquis, Robert Greif, Patricia Llana, David Tyrell, and Bruce Wilson—presented ten papers during the conference.

Read on for brief summaries of the ten papers presented in Columbia.

Controls to Eliminate Broken Rails in Service

By John Tunna (FRA), Jeff Gordon (FRA), David Y. Jeong (Volpe), and Carlo Patrick (FRA)

Broken rails are a leading cause of derailments. Broken rails happen when there are internal faults or cracks in the rail. These faults or cracks can grow due to the weight of trains traveling over them or environmental conditions, and can lead to failure. This report presents a fault tree diagram as an analysis tool for government and industry players working to reduce and prevent broken rails.

Broken rails are a leading cause of derailments. Broken rails happen when there are internal faults or cracks in the rail. These faults or cracks can grow due to the weight of trains traveling over them or environmental conditions, and can lead to failure. This report presents a fault tree diagram as an analysis tool for government and industry players working to reduce and prevent broken rails.

The fault tree presented in this paper organizes the underlying causes of broken rails into two umbrella categories: a defect that reaches a critical size and is not identified during inspection, or rail that is subjected to higher stresses than usual. The paper shows how causes of real-life derailments map onto the fault tree.

FRA and industry have developed regulations and procedures to avoid rail faults, but recent accidents caused by broken rails show that more needs to be done. This fault tree is one way to visualize the causes of broken rails, and it shows that only one thing needs to go wrong before there is increased potential for a broken rail.

Rail Integrity Experience on the Washington Metro System

By Benjamin Frison (Washington Metropolitan Area Transit Authority) and David Y. Jeong (Volpe)

This paper describes rail integrity issues that the Washington Metro rail system has been managing, particularly the development and growth of cracks and defects inside rail heads. The authors present analysis results that can help researchers and Washington Metro safety engineers understand the mechanics of how rails break, including the following most common reasons for broken rails:

This paper describes rail integrity issues that the Washington Metro rail system has been managing, particularly the development and growth of cracks and defects inside rail heads. The authors present analysis results that can help researchers and Washington Metro safety engineers understand the mechanics of how rails break, including the following most common reasons for broken rails:

- Temperatures below neutral or stress-free levels

- Lack of fracture toughness in the rail steel

- Residual stress in the rail

This paper points out that most broken rails occur during cold temperatures in Washington, D.C. One analysis result shows that the time for a defect to grow from barely detectable to a size where failure would be expected is 3 to 5 years on the segment of the Washington Metro system where the Blue, Orange, and Silver lines converge. If ridership increases and trains with more cars become prevalent, this slow crack growth life will shorten.

On Railroad Tank Car Puncture Performance: Part I – Considering Metrics

By David Y. Jeong and Benjamin Perlman (Volpe), and Karl Alexy and Francisco González III (FRA)

A hazardous material tank car that is punctured during an accident can cause serious consequences, including loss of life. FRA recently issued new regulations to require head shields for railroad tank cars carrying high-hazard flammable liquids, which include crude oil and ethanol. Regulatory agencies in the U.S. and Canada are now considering performance-based requirements to reduce negative outcomes when tank cars are punctured.

Part I of this paper discusses the following four metrics researchers can use to characterize how well railroad tank cars perform against puncture:

- Highest impact speed the tank car can withstand—called threshold puncture speed

- Peak impact force

- Puncture energy

- Probability that hazardous material will be released if there is an accident

On Railroad Tank Car Puncture Performance: Part II – Estimating Metrics

By David Y. Jeong, Michael E. Carolan, and Benjamin Perlman (Volpe)

Part II of this paper describes a multidisciplinary approach that can be used to develop engineering tools to estimate the performance metrics outlined in Part I. This approach includes physical crash testing, computational models, mathematical models, probabilistic models, and a strong understanding of uncertainties, which is helpful in establishing credible results.

Credible models and results provide the foundation for research on how well tank cars can withstand puncture incidents, and the basis for developing performance-based requirements for tank cars that are strong enough to prevent or reduce hazardous material release.

Finite Element Bond Modeling for Indented Wires in Pretensioned Concrete Crossties

By Hailing Yu and David Y. Jeong (Volpe)

Crosstie manufacturers increasingly use wires that have indents on them to improve the bond between prestressed steel and concrete in concrete ties used on rail lines. There is a large body of experimental testing on about a dozen common wires, but there is less research on the modeling of the bond of indented wires. This paper develops three mathematical models for three types of indented wires with spiral or chevron indent patterns.

Combined with two previously developed bond models for a smooth wire and a seven-wire strand, the bond models for the indented wires in this paper round out a comprehensive set of bond models now available for studying concrete tie behavior.

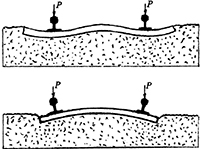

Estimating Deterioration in the Concrete Tie-Ballast Interface Based on Vertical Tie Deflection Profile: A Numerical Study

By Hailing Yu (Volpe)

The bed on which rail ties are laid—called track ballast—is usually made of crushed stone. When ties are made of concrete, the physical interaction between the tie and ballast can lead to abrasion on the bottom of the tie. The ballast may also become pulverized, or there may be gaps between ballast and tie. All of these conditions can lead to premature failure of concrete ties, and ultimately derailment.

The bed on which rail ties are laid—called track ballast—is usually made of crushed stone. When ties are made of concrete, the physical interaction between the tie and ballast can lead to abrasion on the bottom of the tie. The ballast may also become pulverized, or there may be gaps between ballast and tie. All of these conditions can lead to premature failure of concrete ties, and ultimately derailment.

Existing technologies cannot assess defects where a concrete tie and ballast meet. Optical methods cannot see tie-ballast interfaces, and it is difficult with radar and ultrasonic methods to distinguish a defected interface from a normal one.

FRA recently solicited proposals for inspection technologies that can measure anomalies in a tie’s bottom surface and indicate that something is wrong with the ballast interface. The author assesses several simulation models developed at Volpe and finds it possible to use the vertical deflection profile of a tie—the shape and how much a tie deforms under loading when ballast support changes—to assess tie-ballast interface conditions.

Dynamic Wheel-Rail Forces on Mismatched Joints With Ramps

By Brian Marquis and Robert Greif (Volpe)

When a new section of rail is joined to an older section of rail, the older rail is often worn and physically shorter than the new rail. Trains traveling from the new section to the older section will drop slightly due to the mismatch in vertical height. This mismatch can lead to high impact forces, deterioration, and early failure of components in the track structure. Ramps between mismatched rails at joints can reduce these problems.

The authors use computer models to investigate optimal designs for ramps that can ease the transition between two sections of rail. They recommend that the length of the ramp be 100 times the height of the vertical height mismatch; if there is a quarter-inch mismatch, the ramp should be 25 inches long. Future work will try to validate this recommendation by examining how different vehicle types affect ramps, and how ramps affect wheel unloading and forces between wheel and rail.

Two sections of rail at different heights joined by a ramp. (Volpe photo)

Conventional Locomotive Coupling Tests: Test Requirements and Pre-Test Analysis

By Patricia Llana and David Tyrell (Volpe), and Przemyslaw Rakoczy (Transportation Technology Center)

When a locomotive collides with a passenger car, the locomotive can override the passenger car and have devastating consequences for passengers and crew. Crash energy management (CEM) is an engineering design strategy that investigates technologies that can absorb energy produced by a collision and focus crushing elements away from passengers and crew.

CEM includes components such as pushback couplers, which retract when overloaded, and deformable anti-climbers, which crush in a graceful manner. These components inhibit override, which can happen when the strong underframe of one vehicle impacts the weaker superstructure of another vehicle.

This paper is part of a larger FRA and Volpe effort to show that push-back couplers can be designed that do not inadvertently trigger under normal operating conditions even when fully loaded with cargo or passengers, and that they only trigger during collisions. In this paper, the authors detail the test requirements and analysis predictions for collision tests between a locomotive and a passenger car with conventional couplers.

FRA and Volpe are also planning car-to-car tests of CEM locomotives. These tests will allow FRA to thoroughly evaluate CEM-equipped locomotive crashworthiness performance compared to previously tested conventional locomotives.

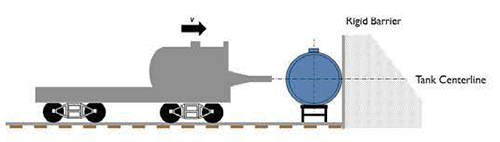

Liquefied Natural Gas Tender Crashworthiness in Train-to-Train Collisions

By David Tyrell (Volpe)

The North American rail industry is developing technology to reliably and safely use liquefied natural gas (LNG) as fuel for locomotives. To accommodate the desired range on freight locomotives and be able to handle the cryogenic aspects of LNG, fuel tanks are designed as separate vehicles called tenders.

The author describes structural features of an LNG tender sandwiched between two six-axle locomotives. These features include a strong underframe and energy absorbing components, and are intended to provide crashworthiness during a train-to-train collision. The goal is to provide a level of crashworthiness equal to that of diesel fuel tanks.

Reducing the Harm in Rail Crashes: Analysis of Injury Mechanisms and Mitigation Strategies

By Bruce Wilson and David Tyrell (Volpe)

Rail passenger travel is very safe, and passenger train accidents are rare. But rare events in complex systems are notoriously difficult to analyze. There are too few accidents to provide data needed for even a moderate degree of mathematical confidence in statistical analyses. Analyses of similar data in the medical and scientific fields are prone to biases of the researchers, sometimes in subtle ways.

Documenting the analysis process and covering a variety of historical accidents allows a wide audience to understand how injuries and fatalities occur in passenger train accidents and, most importantly, helps the rail community prioritize research on mitigation strategies.

The authors analyze 23 commuter and inter-city passenger train accidents over the past 20 years, and assesses the potential effectiveness of various injury mitigation strategies. The strategies with the greatest potential to increase passenger safety are interior occupant protection, coupler integrity, end structure integrity, side structure integrity, and glazing system integrity. The authors recommend that these strategies be researched further.

The aftermath of a head-on collision in the Chatsworth district of Los Angeles, one of 23 accidents analyzed by the authors. (Volpe photo)

Volpe Papers from the 2016 Joint Rail Conference

- Controls to Eliminate Broken Rails in Service

- Rail Integrity Experience on the Washington Metro System

- On Railroad Tank Car Puncture Performance: Part I – Considering Metrics

- On Railroad Tank Car Puncture Performance: Part II – Estimating Metrics

- Finite Element Bond Modeling for Indented Wires in Pretensioned Concrete Crossties

- Estimating Deterioration in the Concrete Tie-Ballast Interface Based on Vertical Tie Deflection Profile: A Numerical Study

- Dynamic Wheel-Rail Forces on Mismatched Joints With Ramps

- Conventional Locomotive Coupling Tests: Test Requirements and Pre-Test Analysis

- Liquefied Natural Gas Tender Crashworthiness in Train-to-Train Collisions

- Reducing the Harm in Rail Crashes: Analysis of Injury Mechanisms and Mitigation Strategies