Rail Innovations Throttle Up at Volpe

From energy efficiency to fuel tank standards, Volpe researchers have a hand in just about every engineering discipline within the rail sector, supporting the Federal Railroad Administration’s Office of Research, Development, and Technology.

Volpe’s range of rail expertise was on display in March at the 2015 Joint Rail Conference in San Jose, California. Six Volpe staff—Adrian Hellman, Karina Jacobsen, Brian Marquis, Patricia Llana, David Tyrell, and Hailing Yu—presented seven papers during the conference, which examined A Century of Innovation: Heavy Haul to High-Speed Rail.

Want to find out about recent advances in rail research? Read on for brief summaries of the seven papers presented in San Jose.

Study on Improving Rail Energy Efficiency (E2): Best Practices and Strategies

By Dr. Aviva Brecher (Volpe) and Melissa Shurland (Federal Railroad Administration)

This report is an overview of a longer Volpe-authored report that reviews strategies and technologies, from the U.S. and abroad, that can improve environmental performance in a cost-effective way for the rail sector.

This report is an overview of a longer Volpe-authored report that reviews strategies and technologies, from the U.S. and abroad, that can improve environmental performance in a cost-effective way for the rail sector.

Among the technologies highlighted in the report are rechargeable energy storage systems that can store and deliver on-demand kinetic energy, which would otherwise be lost during braking. Major railroads are also exploring the use of alternative fuels, such as biodiesel, hydrogen fuel, compressed natural gas, and liquefied natural gas.

Partnerships across federal agencies encourage long-term research and can help spread new technologies—as can Federal Railroad Administration (FRA) partnerships with trade associations and regional and state environmental protection agencies.

Liquefied Natural Gas Tender Crashworthiness Research

Liquefied Natural Gas Tender Crashworthiness Research

By David Tyrell

The North American rail industry is developing technology to reliably and safely use liquefied natural gas (LNG) as locomotive fuel. Researchers are developing LNG fuel cars—known as tenders—that can carry sufficient fuel for desired operating ranges and that can handle cryogenic temperatures.

This paper describes some of the technical information needed to formulate crashworthiness standards for liquefied natural gas tenders, and facilitates industry efforts to use natural gas as a locomotive fuel.

To help develop information needed for effective crashworthiness standards, Tyrell explores five scenarios indicative of the types of incidents that fuel cars experience: a train-to-train collision, a grade-crossing collision, and three derailment scenarios.

Finite Element Bond Models for Seven-Wire Prestressing Strands in Concrete Crossties

By Hailing Yu and David Jeong

Railroad ties anchor rails and distribute rail loads into the ballast bed. The ties maintain track gauge and rail inclination. But, when ties fail, derailments can occur.

Around the world, concrete ties are replacing wooden ties in certain heavy haul or high speed applications. A concrete tie is made by embedding prestressing steel wires or strands in concrete. The pretension in the steel reinforcement is released when the concrete tie is manufactured. The bond where steel and concrete meet transfers prestresses to the concrete, creating an initial compressive stress state in concrete. This initial compression allows the ties to carry and distribute very high vehicle loads. The bond between steel reinforcements and concrete is vital to maintaining the strength and structural integrity of concrete ties.

This report presents several mathematical models that inform the body of knowledge on the testing and characterization of concrete tie bonds with a special class of steel reinforcement called seven-wire strands.

Preliminary Analysis of LED-Enhanced Signs at a Passive Rural Level Crossing

By Adrian Hellman and Aaron Lamplugh

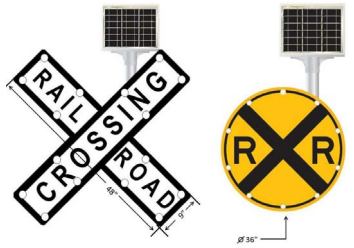

If you flash lights at drivers, will they slow down? This report presents the findings of a study on whether light-emitting diode (LED) warning signs affect how quickly drivers approach rural rail crossings.

If you flash lights at drivers, will they slow down? This report presents the findings of a study on whether light-emitting diode (LED) warning signs affect how quickly drivers approach rural rail crossings.

Two LED crossbuck signs were installed on either side of a rail crossing in Swanton, Vermont. For one month before the new signs were installed, Volpe researchers measured vehicle speeds at the approach to the crossing with existing regular crossbuck signs in place. After the LED crossbuck signs were installed, there was a one-month novelty period to let drivers become accustomed to the new technology. Volpe researchers then used radar and video to measure for two weeks how the new signs impacted driver speeds.

The authors found that mean vehicle speeds at the approach to the crossing decreased after LED crossbuck signs replaced the regular crossbuck signs. This trend was especially noticeable for nighttime measurements, which showed a decrease in mean vehicle speeds of up to 3.3 miles per hour. Future research should focus on potential long-term changes in vehicle speeds resulting from the LED sign technology.

High-Speed Curving Performance of Rail Vehicles

By Brian Marquis and Robert Greif

This paper provides industry insight into the relationships between the wheel and rail forces that a train generates when negotiating a curve at high speeds. The idea is simple: the less a train has to slow down to safely negotiate a curve, the less time is spent getting passengers and goods to their destinations.

Volpe's findings in this report, which examined rigid truck designs, can inform industry decisions on wheel framework design and track layouts for high-speed operations, and can help analysts interpret results of wheelset testing with Amtrak’s Acela high-speed trains.

Results of a Conventional Fuel Tank Blunt Impact Test

By Karina Jacobsen and Michael Carolan

Safety is the rail sector’s highest priority, and FRA is developing strategic designs that improve the structural integrity of new fuel tanks. That’s why FRA asked Volpe to study how conventional fuel tanks on passenger trains withstand impacts.

Volpe’s tests on fuel tanks in Pueblo, Colorado, showed that tank strength is associated with where baffles—a part that reinforces the tank and keeps fuel from sloshing—are located inside the tank, and what they are made of.

Locomotive Crash Energy Management Test Plans

By Patricia Llana

Collisions between trains are rare, but when they occur they create a tremendous amount of energy that must be dissipated. One potential outcome of a train-to-train collision is that one train overrides the other—that it goes over other the vehicle. During a collision, locomotives are particularly susceptible to override, which can be catastrophic.

Crashworthy components can be integrated into the front of a locomotive to inhibit override in the event of collision. Research is ongoing to retrofit these crashworthy components onto conventional locomotives and conduct full-scale dynamic impact tests of colliding cars, as well as colliding trains.

Crashworthy components can be integrated into the front of a locomotive to inhibit override in the event of collision. Research is ongoing to retrofit these crashworthy components onto conventional locomotives and conduct full-scale dynamic impact tests of colliding cars, as well as colliding trains.

This report lays out the parameters for FRA’s locomotive crashworthy test program, including coupling tests, vehicle-to-vehicle tests, and train-to-train tests. Those tests will demonstrate the in-service and crashworthiness performance of locomotive components that can prevent override.

Volpe Papers from the 2015 Joint Rail Conference

- Study on Improving Rail Energy Efficiency (E2): Best Practices and Strategies

- Liquefied Natural Gas Tender Crashworthiness Research

- Finite Element Bond Models for Seven-Wire Prestressing Strands in Concrete Crossties

- Preliminary Analysis of LED-Enhanced Signs at a Passive Rural Level Crossing

- High-Speed Curving Performance of Rail Vehicles

- Results of a Conventional Fuel Tank Blunt Impact Test

- Locomotive Crash Energy Management Test Plans