New Seat Belt Locking Mechanisms Aim to Improve Child Safety

The U.S. Department of Transportation’s (U.S. DOT) highly competitive Small Business Innovation Research (SBIR) program awards contracts to domestic small businesses to pursue research on and develop innovative solutions to our nation’s transportation challenges. Small businesses that participate in this program have developed numerous new and innovative technologies that have benefitted the Department and the public, while providing a basis for growth for small businesses.

With support from the U.S. DOT SBIR program and the National Highway Traffic Safety Administration (NHTSA), Tool, Inc. designed and developed prototype seat belt retractor countermeasures aimed at reducing the risk of seat belt entrapment.

Most seat belts have locking mechanisms built into the retracting mechanism. Called an Automatic Locking Retractor (ALR), this seat belt design is a safety feature intended to hold a child car seat in place. In misuse conditions, such as when a child pulls a seat belt all the way out, the ALR activates, locking the seat belt in place and tightening it until it is reset by feeding the belt back into the retractor. If the seat belt is wrapped around a child’s head, neck, or waist when the ALR activates, the seat belt can strangle or seriously injure the child.

The Challenge

To reduce the risk of seat belt entrapment, NHTSA sought designs for countermeasures that would prevent entrapment while still meeting seat belt lockability requirements. Tool, Inc., a product design and development firm in Marblehead, MA, designed and developed prototype designs over the course of a Phase I and Phase II SBIR effort.

The Technology

During Phase I, Tool, Inc. developed three seat belt countermeasure designs based on NHTSA’s data on entrapment cases. Tool, Inc. then worked with NHTSA to refine concepts for engineering and prototyping. Over the course of multiple design cycles, Tool, Inc. developed three prototypes, which were evaluated at the University of Michigan Transportation Research Institute (UMTRI).

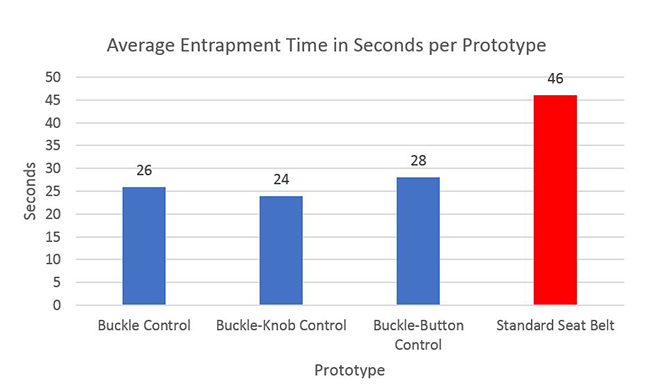

The team’s prototypes—Buckle Control, Buckle-Knob Control, and Buckle-Button Control—repeatedly demonstrated reduced entrapment times compared to the standard seat belt. These designs change how the locking mechanism engages and disengages, either through moving control of the locking mechanism to a button elsewhere in the car cabin, or through only activating the locking mechanism when the seat belt is buckled. The new designs give parents more control over the locking mechanism, allowing them to quickly free an entrapped child.

All three of the prototype countermeasure designs that Tool, Inc. developed reduced entrapment time. (Chart provided by Tool, Inc.)

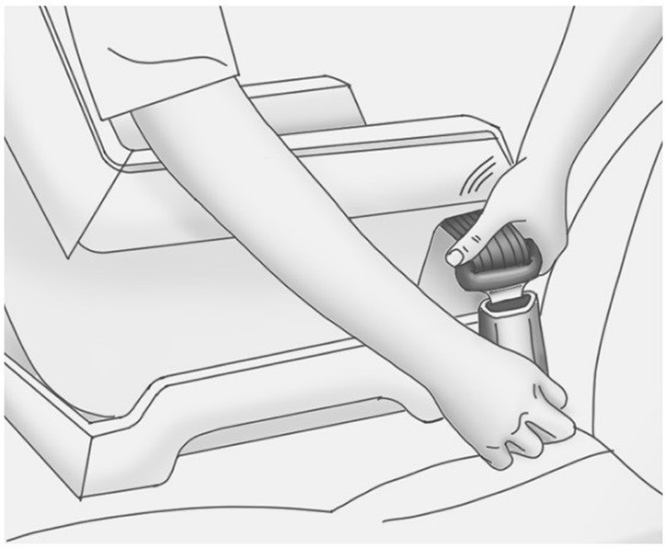

Prototype 1: Buckle Control

The Buckle Control prototype retractor locks the same way as a standard seat belt retractor when the shoulder belt is completely pulled out, with two key differences:

- It only switches to the Automatic Locking Retractor (ALR) when the seat belt is buckled.

- The retractor goes from the ALR to the Emergency Locking Retractor (ELR) when the buckle is released, so the belt does not need to be fed all the way back into the retractor to disengage the ALR.

The ALR makes it possible to secure a child seat without a seat belt locking clip, while the ELR allows the seat belt to extend and retract freely, locking only during sudden stops or impacts.

The Buckle Control prototype. (Tool, Inc. image)

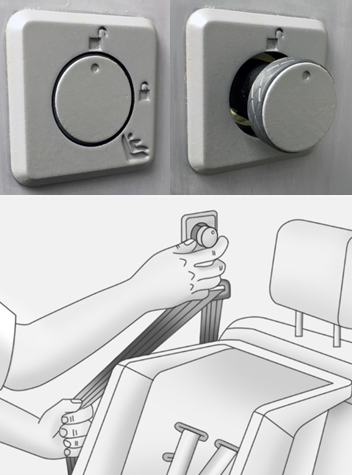

Prototype 2: Buckle-Knob Control

The Buckle-Knob Control prototype has a knob concealed in the vehicle pillar, a vertical support that holds up the car’s window. This knob moves out from its stowed position when the shoulder belt is pulled all the way out of the retractor. The user must turn the knob to lock the retractor. As the webbing feeds into the retractor, the knob returns to the stowed position. The retractor is unlocked by releasing the buckle.

The Buckle-Knob Control prototype. (Tool, Inc. image)

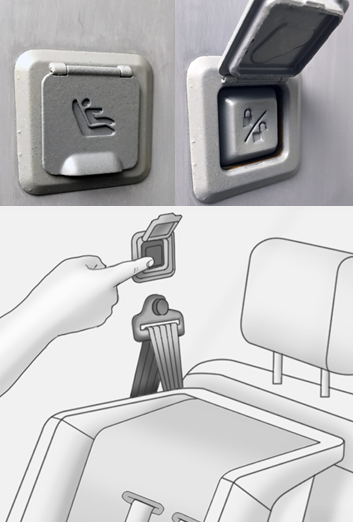

Prototype 3: Buckle-Button Control

The Buckle-Button Control prototype has a button covered by a small door on the vehicle pillar. When the button is pressed, it locks the retractor if the belt is buckled. The retractor is unlocked by pressing the button again or by releasing the buckle.

The Buckle-Button Control prototype. (Tool, Inc. image)

Phase II: Evaluating the Prototypes

The Tool, Inc. project entered Phase II with the assessment of a new design concept, the Buckle-Switch prototype, and the Buckle-Control prototype.

The Buckle-Switch concept builds on the Buckle-Control prototype but adds a switch to allow passengers to keep the retractor out of locking mode if desired. With this combined system, the ALR cannot be activated unless the switch on the buckle is shifted from adult to child restraint system mode.

Initial Buckle-Switch prototype design developed in the second round of evaluation at UMTRI. The concept builds upon the Buckle-Control device but adds a switch to allow passengers to keep the retractor from locking. (Tool, Inc. image)

How SBIR Helps

Tool, Inc. is working to commercialize the devices, which, if installed in automobiles, could prevent injuries and deaths caused by entrapment.

The SBIR program supported Tool, Inc. throughout the commercialization process, including during design and development, evaluation, and patent work.

“The SBIR funding helped our company to move along a commercialization path,” said Jason Sidman, vice president of business development at Tool, Inc. “Without this funding, we could not have gone through the necessary product development iterations, including evaluation at a world-class research institute, to hone in on the most effective design.”

Small Business: Tool, Inc.

Principal Investigator: William Liteplo

Project: Device to Address the Competing Needs of Ensuring Lockability of Seat Belts and Mitigating Entrapment Risk in Misuse Conditions

Funding Agency: National Highway Traffic Safety Administration

Phase I: $149,995

Phase II: $499,210